Cantera Flamelet Generation

A two-point flame control method is implemented in Cantera, which mirrors the standard arclength continuation methods that are used in codes such as FlameMaster. The two-point flame control method is used to generate flamelets that are along the unstable burning branch of a counterflow diffusion flame.

The Flamelet Table Tool can read in these Cantera flamelets and generate flamelet tables.

The flamelet generation script is located in the utilities/cantera_flamelet_generator directory of the Flamelet Table Tool. The script is called

flamelet_gen.py. The script takes 1 argument, which is the name of the control file.

When generating a flamelet table using Cantera flamelets, a few extra Flamelet Table Tool control file options are required. These options are:

FLAMELETTYPE Cantera

FUEL H2

Z_PRUNE_THRESHOLD 1e-3

The FUEL is simply the species that is the fuel in the counterflow diffusion flame. The Z_PRUNE_THRESHOLD is the threshold value

that is used to reduce the size of the Cantera flamelets. Cantera solves the counterflow diffusion flamelet in the physical domain, which means that

the strained flame becomes very thin and as such, much of the 1D domain is either pure fuel or oxidizer with a thin flame zone. The threshold value

is used to remove data points that are below/above this threshold value on the fuel/oxidizer side of the flamelet, respectively.

Cantera Control File

A simple YAML control file is used to specify the inputs for the flamelet generation process is shown below. We will use this example to explain the various options that are available in the control file.

# A run using the same setup as a known case that was run using FlameMaster, for the

# purposes of comparing the final results.

# Input parameters

p: 5.4e6 # pressure [Pascals]

fuel_inlet_temp: 800.0 # fuel inlet temperature [Kelvin]

oxidizer_inlet_temp: 711.0 # oxidizer inlet temperature [Kelvin]

fuel_mdot: 0.05 # kg/m^2/s

oxidizer_mdot_factor: 1.0 # Factor to adjust oxidizer mass flow rate

width: 20.0e-3 # Distance between inlets [m]

# Mass Fraction composition

oxidizer_composition: 'O2:0.9449, H2O:0.0551' # oxidizer composition (right)

fuel_composition: 'H2:0.4018, H2O:0.5982' # fuel composition (left)

# Reaction mechanism

mechanism: 'mechanism/H2.yaml'

# Optional: explicit phase name from the mechanism YAML

# phase: gas

# Optional: override transport model for the selected phase

# transport_model: mixture-averaged

# Generate the initial condition for the desired pressure by walking

# the pressure up from p_start until p is reached.

pressure_increment_initial_condition:

p_start: 101325

increase_factor: 1.05

maximum_increment: 5.0e5

minimum_increment: 1.0e2

# Solver settings

steady_tolerances:

relative_tolerance: 1e-6

absolute_tolerance: 1e-9

refine_criteria:

ratio: 15

slope: 0.25

curve: 0.08

prune: 0.04

# Two-Point Controls

spacing: 0.97

initial_temperature_increment: 20

maximum_temperature_increment: 20

temperature_increment_growth_rate: 1.08 #Give this as a factor where 1.02 would be a 2% increase per iteration

maximum_change_in_max_temperature: 60 # This prevents the maximum flame temperature from dropping too fast

increment_direction: decreasing # Valid values are 'increasing' or 'decreasing'

# Diagnostics

log_level: 0 # amount of diagnostic output (0 to 9)

generate_diagnostics: True

# Restart

restart: flamelet_205.yaml

Below is a table that summarizes what each input parameter does:

Input Parameter |

Description |

|---|---|

|

Pressure in Pascals |

|

Fuel inlet temperature in Kelvin |

|

Oxidizer inlet temperature in Kelvin |

|

Fuel mass flow rate in kg/m^2/s |

|

Factor to adjust the oxidizer mass flow rate (default is same velocity as fuel stream) |

|

Distance between inlets in meters |

|

Oxidizer composition (right) in mass fractions, in a dictionary form |

|

Fuel composition (left) in mass fractions, in a dictionary form |

|

Path to the reaction mechanism file (YAML mechanism file) |

|

Optional phase name inside |

|

Optional transport model override (must not be |

|

Optional block used to walk pressure from |

|

Starting pressure for the pressure walk in Pascals |

|

Multiplicative growth factor for pressure step size after successful solves (default 1.05) |

|

Upper bound on the pressure step size in Pascals |

|

Lower bound on the pressure step size before giving up in Pascals (default 100.0) |

|

Optional explicit starting step size in Pascals (default is |

|

Divisor applied to pressure step size after a failed solve (default 2.0) |

|

Optional EOS intent flag/validation (e.g., |

|

Tolerances for steady-state solver (same as Cantera’s steady tolerances) |

|

Criteria for refining the flamelet solution (same as Cantera’s refine criteria) |

|

Flag for whether to perform automatic continuation (valid values are ‘true’ or ‘false’, default is ‘true’) |

|

Percentage of maximum flame temperature where control points will be located |

|

Starting temperature increment between flamelet solutions |

|

Maximum allowable temperature increment between flamelet solutions |

|

Growth rate of temperature increment allowed per iteration |

|

Maximum change in maximum flame temperature |

|

Direction of temperature increment (valid values are ‘increasing’ or ‘decreasing’, default is ‘decreasing’) |

|

Amount of diagnostic output (based on Cantera’s loglevel) |

|

Whether to generate diagnostics |

|

Path to the restart file |

The maximum_temperature_increment input variable is related to the temperature decrement that is attempted during a two-point flame control

solution. This is the amount by which the code will attempt the lower the temperatures at the control points. Larger values can be unstable, so the

user can set a maximum allowable temperature decrement. The temperature_increment_growth_rate is a factor that is used to increase the temperature

increment between flamelet solutions. This is useful for speeding up the flamelet generation process. The maximum_change_in_max_temperature is used

the prevent the maximum flame temperature from dropping too fast between two flamelet solutions. This occurs often during the march down the unstable burning

branch of the counterflow diffusion flame, so this option allows a user to have more points along the unstable burning branch.

If the generate_diagnostics option is set to True, the flamelet generator will create an output folder that contains plots of the flamelet solution

variables for each flamelet solution. This is useful for diagnosing issues with the flamelet generation process.

The solver is often run starting from a solution that is on the burning branch. When Cantera is generating solution along the stable burning branch,

the two-point flame control method is not enabled and successive solutions are simply generated by increasing the mass flow rates of the fuel and

oxidizer streams. At some point, the solver will be unable to generate any more non-extinguished solutions, and the flamelet generation script will

switch to the two-point flame control method to march down the unstable branch. If an error occurs during the flamelet generation process, a user would

have to restart the entire process starting on the burning branch again. The restart option allows a user to restart the flamelet generation process

from an existing flamelet solution. This flamelet generation script will load this solution and activate the two-point flame control and continue the

marching process of lowering the flame temperature.

The numerical solver options for Cantera can be set by providing the steady_tolerances and refine_criteria options. The steady_tolerances option

control the convergence criteria for the Cantera 1D flame solver. The refine_criteria option controls the criteria for refining the flamelet solution. This

controls how additional points are place dynamically in the solution during the generation of each solution. Cantera defines the refinement options as:

Refinement Parameter |

Description |

|---|---|

|

Maximum ratio between grid spacing at adjacent intervals. E.g. (x[j+1] - x[j]) / (x[j] - x[j-1]) < ratio |

|

Maximum fractional change in the value of each solution component between adjacent grid points |

|

Maximum fractional change in the derivative of each solution component between adjacent grid points. |

|

Threshold for removing unnecessary grid points. prune should be smaller than both slope and curve. Set prune <= 0 to disable pruning. |

The refiner can often add many additional points to the domain in the region where the solution is essentially constant (due to the flame being very thin). Adjusting the refinement criteria can help to keep the number of points in the domain to a minimum and to cluster them where they are needed most in the regions where the solution is changing rapidly in the vicinity of the flame. The values that are shown the sample YAML control file above are good starting values for the refinement criteria. The user may need to adjust these values based on the flamelet solutions that are generated.

Real-Gas Simulation

If the eos option is set to peng_robinson in the flamelet generator control file, then the script will attempt to extract the

Peng-Robinson parameters from Cantera. To have Cantera use the cubic Peng-Robinson equation of state, the input YAML mechanism file must have

the Peng-Robinson value set for the thermo attribute.

You should also set the phase option in the control file to the Peng-Robinson phase name in the mechanism file. If phase is not

provided, Cantera loads the default phase, which is often ideal gas.

mechanism: 'mechanism/my_realgas_mech.yaml'

phase: gas_pr

eos: peng_robinson

transport_model: mixture-averaged

phases:

- name: gas

thermo: Peng-Robinson

elements: [N, O, H]

species: [N2, O2, H, OH, O, H2, H2O, HO2, H2O2]

kinetics: gas

reactions: all

transport: mixture-averaged

state:

T: 300.0

P: 1.01325e+05

The current default behavior of Cantera when the Peng-Robinson equation of state is specified is to search the input YAML file for either the

critical-parameters attribute with the critical-temperature, critical-pressure, critical-volume, critical-compressibility,

and acentric-factor defined under that attribute.

species:

- name: N2

composition: {N: 2}

thermo:

model: NASA7

temperature-ranges: [300.0, 1000.0, 5000.0]

data:

- [3.298677, 1.4082404e-03, -3.963222e-06, 5.641515e-09, -2.444854e-12,

-1020.8999, 3.950372]

- [2.92664, 1.4879768e-03, -5.68476e-07, 1.0097038e-10, -6.753351e-15,

-922.7977, 5.980528]

transport:

model: gas

geometry: linear

diameter: 3.621

well-depth: 97.53

polarizability: 1.76

rotational-relaxation: 4.0

critical-parameters:

critical-temperature: 126.19

critical-pressure: 3.3958e6

critical-molar-volume: 0.543

critical-compressibility: 0.253

acentric-factor: 0.445

note: '000000'

If the critical parameters are not found in the input YAML file, the Cantera will search for the equation-of-state attribute with the a,

b, and acentric-factor defined under that attribute. For gas species that are ideal, specifying the a and b parameters to

be 0.0 will result in that species being treated as ideal in the mixture Peng-Robinson equation of state.

- name: H

composition: {H: 1}

thermo:

model: NASA7

temperature-ranges: [300.0, 1000.0, 5000.0]

data:

- [2.5, 0.0, 0.0, 0.0, 0.0, 2.547162e+04, -0.4601176]

- [2.5, 0.0, 0.0, 0.0, 0.0, 2.547162e+04, -0.4601176]

transport:

model: gas

geometry: atom

diameter: 2.05

well-depth: 145.0

equation-of-state:

model: Peng-Robinson

a: 0

b: 0

acentric-factor: 0

As a final search, Cantera will look for a file named critical_parameters.yaml in the same directory as the input YAML mechanism file.

This file is provided by Cantera and is located in the data/ of Cantera. It has a collection of critical parameters for many species, but

it is not exhaustive, so additional entries may need to be added.

Note: Critical pressures are given in Pa, critical temperatures are in Kelvin, and critical volumes are given in m^3/kmol.

Pruning Flamelets

In the utilities/cantera_tools/ directory there is a script that can be used to prune the flamelet solutions that are generated by the Cantera.

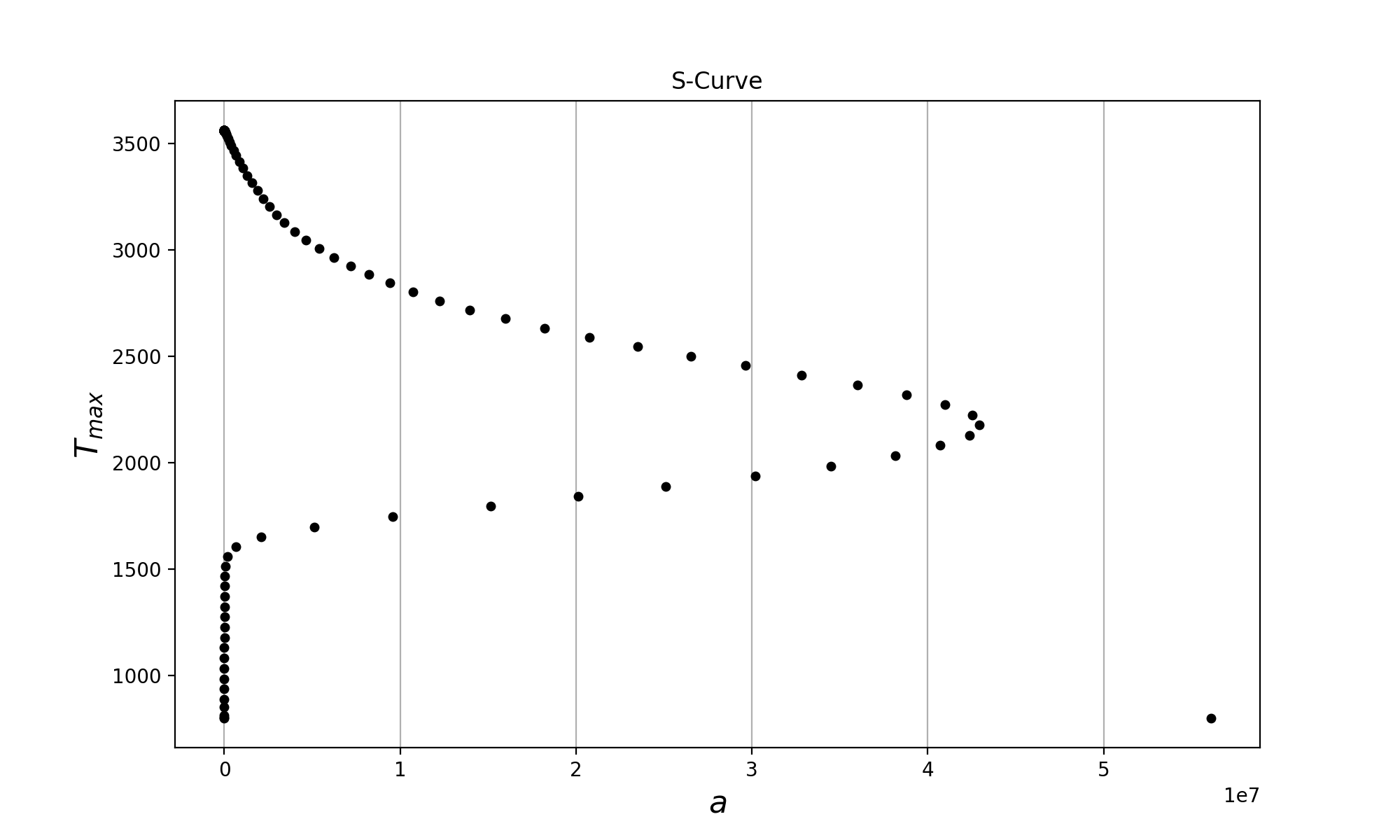

The generation intuition is that a set of solutions that spans in the S-curve with 10 flamelets per decade of strain rate is sufficient. Often times

it is difficult to set up a control file that will generate the exact number of flamelets that are needed, and so it is easier to generate more solutions

than is necessary and then prune away the ones that are not needed. The pruning script is called cantera_flamelet_pruning.py. Using instructions

can be seen by calling the script with no arguments. The arguments and a brief summary of them are shown in the table below.

Argument |

Description |

|---|---|

|

Path to the flamelet solutions (can be absolute or relative) |

|

Flamelet solutions that are closer together than this distance are removed. |

|

Directory where the pruned flamelet solutions will be output to |

The arclength is computed from the maximum temperature versus mean strain rate plot of all of the flamelet solutions. The arclength

is the simple euclidean distance between two points on the S-curve. The script will remove flamelet solutions that are closer together

than the minimum_arclength value.

A sample S-curve for a H2/O2 reaction in the \(T_{max}\) - \(a_{mean}\) space.

General Guidance

Cantera solves the axisymmetric counterflow diffusion flame in the physical domain, and as such, the choice of the initial mass flow rates of the fuel and

oxidizer streams as well as the domain width are important factors to consider. The initial solution should always be located within the domain and should

not be too close to the fuel or oxidizer inlets. The flamelet generation script uses a mass flow balance to estimate the velocity of the oxidizer

stream. For some cases, this will not result in a flame solution that is located away from the boundaries. In cases where the oxidizer stream needs to be

adjusted, the user can add the oxidizer_mdot_factor option to the control file. This option is a factor that is used to adjust the oxidizer mass flow

rate. A value of 1.0 will use the mass flow rate that is calculated by the flamelet generation script, while a value of 0.5 will reduce the oxidizer mass

flow rate by half. The default value when it is not specified is 1.0.

From the literature on the two-point control method, it is suggested that the control points be located in regions of high temperature gradient. The

spacing option in the control file is used to specify the percentage of the maximum flame temperature where the control points will be located, which

dictates how far from the peak the control points will be located. In some cases a lower value may be better for flames during the low strain-rate

regime, while a higher value may be better for flames during the high strain-rate regime. The user may need to adjust this value based on the flamelet

solutions that are generated.

If the flamelet generator is started from scratch on the burning branch, then at the end, it uses the history of the traversal of the S-curve to

compute an extinction flamelet by taking the highest strain solution, and then increasing the strain past that point and calling the Cantera solver.

This is what generates the flamelet_0.yaml file. When restarting, this final action will not be performed as the code does not have the full history

from which to estimate the highest strain rate. Under these conditions, a single extinction flamelet can be generated by setting the continuation

option to false in the control file. This disables the two-point control method and simply generates a single flamelet solution based on the

inputs given in the control file (for an extinction flamelet, the mass flow rates need to be set high).