Homogeneous Reactor Flamelet Generation

Overview

The process of generating a suite of Homogeneous-Reactor flamelets that can then be processed into a flamelet table is quite different from that used for 1D diffusion flamelets. With diffusion flamelets (generated using either FlameMaster or Cantera), the typical process involves an automated marching process around the so-called S-curve, in which each point on the S-curve is a distinct flamelet solution at a given strain rate located either on the burning branch, the unstable branch, or the pure-mixing branch. In regards to the Z dimension of the table, each diffusion flamelet spans the entire dimension range (0 < Z < 1), where Z = 0 is pure oxidizer, Z = 1 is pure fuel, and intermediate values contain combusted states and the main flame. When one attempts to aggregate these flamelets into a flamelet table, often a pruning process is required to prevent overlap of neighboring diffusion flamelets in regards to the progress variable dimension (C), which can produce unphysical jumps in the tabulated variables with the final flamelet table. In this regard, it is important to note that flamelet pruning is an inter-flamelet process which involves comparisons between multiple flamelets.

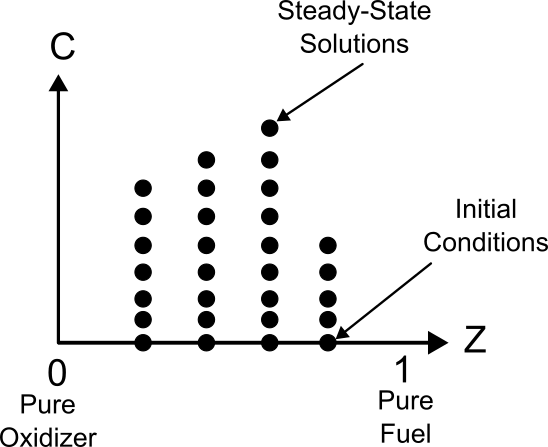

In contrast to diffusion flamelets, individual Homogeneous-Reactor flamelets do not span the Z dimension of the table. In fact, each flamelet corresponds to a single Z value. Consider the diagram shown below.

Simple diagram showing how the homogeneous-reactor flamelets fill the Z-C space.

At any particular value of Z, one specifies a Homogeneous-Reactor initial condition (the C = 0 state) for pressure, specific enthalpy, and species mass fractions by combining the fuel and oxidizer according to the relations shown below.

This initial state is then integrated in time to the final fully-combusted steady-state condition, which is represented in the figure by a vertical line at the given Z value. Having generated all of the individual Homogeneous-Reactor flamelets (one for each Z value), these values can then be aggregated into a flamelet table. Depending on the definition of C, one may need to perform pruning of the flamelets to achieve monotonic C evolution within each homogeneous reactor, but unlike diffusion flamelets, the pruning of any one homogeneous-reactor flamelet is completely independent of the solution in all the other flamelets.

The homogeneous reactor has several utilities in addition to the flamelet generator. These utilities are:

Binary |

Description |

|---|---|

|

Allows a user to examine the equation of state (EOS) that is used in the homogeneous reactor. |

|

The primary tool in the homogeneous reactor for generating flamelets. |

|

A 0D reactor that supports constant pressure or constant volume time integration. |

Handling of Two-Phase Combustion

A gas-phase reaction mechanism augmented with a liquid-phase reaction, phase-state information provided by the Complete Peng-Robinson Equation of State (CPREOS) is required by the reaction library to determine which elements of the complete reaction set are active. The primary principles at play in the method are:

When the mixture is in the liquid phase, only the global liquid reaction is active.

When the mixture is in the vapor phase, only the gas-phase reaction mechanism is active.

When the mixture is two-phase, both the global liquid reaction and the gas-phase mechanism are active.

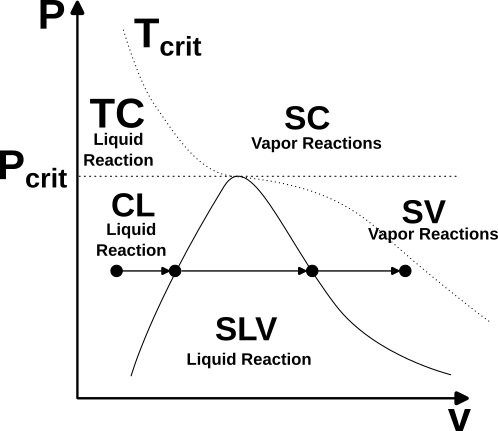

Consider the p-v phase diagram shown in the image below.

Phase diagram showing the regions of the space and the corresponding vapor quality values.

The CPREOS stores not only thermodynamic state variables (such as density, pressure, temperature, etc.), but also the vapor quality of the mixture, designated by the symbol q. The various regions of the space are designated as follows:

CL: Compressed liquid region (P < P_Crit, T < T_Sat)

SLV: Saturated liquid-vapor region (P < P_Crit, T = T_Sat)

SV: Superheated vapor region (P < P_Crit, T > T_Sat)

TC: Transcritical region (P < P_Crit, T > T_Crit)

SC: Supercritical region (P > P_Crit, T > T_Crit)

where P_Crit is the critical pressure, T_Crit is the critical temperature, and T_Sat is the saturation temperature of the current mixture (defined by the molar or mass composition). In the figure, for each of these regions, the corresponding vapor quality value is shown. We note that in the TC region, while the mixture is technically not in a true liquid state, as in the CL region, we have defined a vapor quality of q = 0, so that liquid-liquid combustion simulations can be initiated with the high-density, liquid-like reactant mixtures located there. From these values, we see the following reaction characteristics:

CL, TC: Only global liquid reaction is active

SLV: Both global liquid reaction and gas-phase reaction mechanism active

SV, SC: Only gas-phase reaction mechanism active

These conditions are enforced within the reaction kinetics coding of the Homogeneous Reactor in a relatively simple manner by modifying the concentration of the reactants using the molar vapor quality. Assume, for example, that we have the following liquid reaction:

A + B -> C + D + E + F

The production rate of species C is typically written as follows:

where \(K_f\) is the forward reaction rate in standard Arrhenius rate form, and \(|*|\) represents the molar concentration of any species. However, when dealing with combined mechanisms (containing the liquid reaction and the gas-phase reaction mechanism), the total concentration of species A and B may be distributed between liquid and vapor phases. Because the liquid reaction must only consume the liquid parts of A and B available in the mixture, the production rate of species C in this example is modified to the following:

From this new form, it is clear that when \(q = 1\) (the mixture is 100% vapor), the liquid reaction ceases to produce species C, D, E, and F. A similar strategy is used for the gas-phase mechanism reactions. Consider the following generic forward/reverse elementary reaction that is typical in standard gas-phase mechanisms (this is only one of the reactions in the complete gas-phase mechanism):

G + H <-> I + J

The contribution to the net production rate of species I from this reaction alone is typically written as follows:

where \(K_r\) is the reverse reaction rate in standard Arrhenius form. Since the species I is by definition only to be produced via the reaction of vapor-phase G and H and depleted by the reaction of vapor-phase I and J, the net production rate must be modified to the following:

In a manner similar to the liquid reaction above, when \(q = 0\), the reaction ceases to produce species I (as well as species G, H, and J).

Using Homogeneous-Reactor Flamelets with the Flamelet Table Tool

To use the Homogeneous-Reactor flamelets with the Flamelet Table Tool, the FLAMELETTYPE option in the control file must be set to

homogeneous_reactor. The FUEL option must also be set to the name of the fuel species. An example of the control file options

required for generating flamelet tables using Homogeneous-Reactor flamelets is shown below.

FLAMELETTYPE homogeneous_reactor

FUEL H2

The FUEL is simply the name of the species that is the fuel in the flames.

Flamelet Generation

The flamelet-generator is available to automate the process of generating a suite of 0D flamelets over the Z-space of a

flamelet table. This tool employs essentially the same methods as the reactor tool, but unlike the reactor tool, given a

complete specification of the fuel and the oxidizer, the tool will perform all homogeneous-reactor simulations required to span

the entire Z space at a user-specified resolution. A sample execution command for flamelet-generator is shown below.

flamelet-generator -crit critical-properties -mech H2_ideal -n 201 -P 5.4e+06 -Tf 800 -yf H2 0.4018 -yf H2O 0.5982 -To 711 -yo O2 0.9449 -yo H2O 0.0551 -time 20.0 -of 1 -atol 1.0e-15 -rtol 1.0e-09

The flamelet-generator generates constant pressure solutions. The example above specifies a case where the fuel is a mixture of H2 and

H2O, and the oxidizer is a mixture of O2 and H2O. The mass fractions of the fuel and oxidizer are specified using the -yf and -yo

options, respectively. The temperature of the fuel and oxidizer is specified using the -Tf and -To options, respectively. The

pressure is specified using the -P option. The number of Z points is specified using the -n option. The time to integrate the

homogeneous reactor is specified using the -time option. The output frequency is specified using the -of option. The absolute

tolerance is specified using the -atol option, and the relative tolerance is specified using the -rtol option.

This will generate a set of solutions with the naming convention flamelet_#.dat, where # is the integer index of the Z value, for example

if -n 10 is provided, then flamelet_0.dat, flamelet_1.dat, ..., flamelet_9.dat will be generated.

Creating a YAML Mechanism File

The Homogeneous-Reactor flamelet-generator requires a YAML mechanism file to run. This mechanism file is derived from the Cantera

YAML mechanism file format.

Specification Reactions Involving Liquid Components

Some additional steps are required by the user in specifying species in mechanisms intended to be used for two-phase combustion simulations. The goal of these steps is to aid the reactor library in enforcing the three principles described earlier. A modified syntax .yaml mechanism file is introduced to aid the reactor library.

The gas-phase mechanism RChem3, which is augmented with the liquid reaction shown below will be used to demonstrate this syntax. The liquid reaction is:

equation: CH3NHNH2 + 8.5 NO2 => CO2 + 3 H2O + 2.25 N2 + 6 NO + 3 O2

For a pure gas-phase combustion problem using the RChem3 mechanism, the species subsection of the phases section of the .yaml file looks as follows:

species: [H, H2, O, OH, H2O, HO2, CH2, CH3, CH4, CO, HCO, CH2O, CH3O,

CO2, N, NH, NH2, NH3, N2, NNH, N2H2, NO, HNO, N2O, NO2, HONO, HNO3,

N2O4, CN, HCN, HNC, NCO, CH3NHNH2, CH2NHNH2, CH3NNH2, CH3NHNH, CH3NN,

CH2NNH2, HNCO, CH3NNH, CH3ONO2, AR, O2, H2O2]

In order to assist the reactor library in parsing reactions for the augmented mechanism file that contains the additional liquid reaction, this section must be changed to the following:

species: [H, H2, O, OH, H2O_*, HO2, CH2, CH3, CH4, CO, HCO, CH2O, CH3O,

CO2_*, N, NH, NH2, NH3, N2_*, NNH, N2H2, NO_*, HNO, N2O, NO2_*, HONO, HNO3,

N2O4, CN, HCN, HNC, NCO, CH3NHNH2_*, CH2NHNH2, CH3NNH2, CH3NHNH, CH3NN,

CH2NNH2, HNCO, CH3NNH, CH3ONO2, AR, O2_*, H2O2]

Here, an _ * has been appended to selected species. These selected species are designated as the “two-phase” species

and require augmentation to their names when used later in the mechanism to inform the reaction library which phase of

the species is to be used in a particular reaction. As a general rule, the “two-phase” species list must include all of

the species in the liquid reaction. In this example, all of the species in Equation _ are tagged with the _ * specification.

For the liquid reaction, one must tag the reactants with the _L tag as shown below:

equation: CH3NHNH2_L + 8.5 NO2_L => CO2 + 3 H2O + 2.25 N2 + 6 NO + 3 O2

This tag explicitly tells the reaction library to pre-multiply the concentrations of these reactants by \((1-q)\) when

computing the rates of production of the product species in the liquid equation. In a similar manner, the two-phase species

involved in any of the elementary reactions of the gas-phase part of the mechanism must be tagged with the _V specification.

This tag explicitly tells the reaction library to pre-multiply the concentrations of these reactants by \(q\) when computing

rates of production.

Below are examples of equations from the gas-phase RChem3 mechanism that have been tagged appropriately.

equation: OH + CO <=> H + CO2_V

equation: OH + HCO <=> H2O_V + CO

equation: NNH <=> N2_V + H

equation: N + OH <=> NO_V + H

equation: NH2 + NO_V <=> N2_V + H2O_V

Note: In all of these gas-phase reactions, the concentrations of the untagged species are not, by definition, multiplied by the factor q since the entire concentration must be used. This is because these species are only produced and consumed in the gas-phase reaction set.

Marking Equation of State for Ideal-Gas Species

When the YAML mechanism file is parsed by the reactor library, it constructs the Peng-Robinson equation of state (EOS) for

the mixture. Species that are not explicitly marked as ideal gases in the mechanism file are assumed to be real gases and

thus their critical properties are searched for in the critical-properties.yaml database file. For species that are ideal,

an equation-of-state section must be added to the species entry in the mechanism file. An example of this is shown below for

marking a species as an ideal gas.

phases:

- name: H

composition: {H: 1}

thermo:

model: NASA7

temperature-ranges: [200.0, 1000.0, 3500.0]

data:

- [2.5, 7.05332819e-13, -1.99591964e-15, 2.30081632e-18, -9.27732332e-22,

2.54736599e+04, -0.446682853]

- [2.50000001, -2.30842973e-11, 1.61561948e-14, -4.73515235e-18, 4.98197357e-22,

2.54736599e+04, -0.446682914]

transport:

model: gas

geometry: atom

diameter: 2.05

well-depth: 145.0

equation-of-state:

model: Peng-Robinson

a: 0

b: 0

acentric-factor: 0

Critical Properties File

Any species that is tagged using the _ * marker in the input YAML mechanism file must have its critical properties defined in a file named critical_properties.yaml. This file must be located in the same directory as the input YAML mechanism file. The critical properties file must be in the format shown below. Is has the same format at the standard Cantera critical properties file.

description: |-

These critical properties are used to calculate the a and b parameters for real gas

equations of state, such as Redlich-Kwong and Peng-Robinson.

The a and b parameters can be provided explicitly by the user in the input file. In

the case that they are not provided for a species, and the critical state for the

species is not given in the 'critical-parameters' field of the species entry, Cantera

will search this database for critical properties. If critical properties are not

found and coefficients are not provided, then an error is thrown.

Critical pressures are given in Pa. Critical volumes are given in m^3/kmol.

These critical properties have been compiled from various sources by

C. Karakaya (https://orcid.org/0000-0001-5102-5476)

Notes

1) CH3NHNH2 properties from Physical and Thermodynamic Properties of Hypergolic Propellants - A Review and Update (Arnold 1999)

input-files: critProperties.xml

cantera-version: 2.6.0a3

date: Sat, 20 Nov 2021 22:47:06 -0500

species:

- name: CH3NHNH2

descriptive-name: mmh

molecular-weight: 46.07

critical-parameters:

critical-temperature: 567

critical-pressure: 8.3491e+6

critical-molar-volume: 0.2712

critical-compressibility: 0.474

acentric-factor: 0.425

- name: N2O4

descriptive-name: nitrogen-tetroxide

molecular-weight: 92.02

critical-parameters:

critical-temperature: 431.4

critical-pressure: 1.023e+07

critical-molar-volume: 0.1678

critical-compressibility: 0.473

acentric-factor: 0.834

- name: NO2

descriptive-name: nitrogen-dioxide

molecular-weight: 46.01

critical-parameters:

critical-temperature: 431.4

critical-pressure: 1.013e+07

critical-molar-volume: 0.1697

critical-compressibility: 0.4793

acentric-factor: 0.851

- name: CO2

descriptive-name: carbon-dioxide

molecular-weight: 44.01

critical-parameters:

critical-temperature: 304.2

critical-pressure: 7.39e+06

critical-molar-volume: 0.0948

critical-compressibility: 0.275

acentric-factor: 0.228

- name: H2O

descriptive-name: water

molecular-weight: 18.0153

critical-parameters:

critical-temperature: 647.13

critical-pressure: 2.194e+07

critical-molar-volume: 0.056

critical-compressibility: 0.228

acentric-factor: 0.343

- name: N2

descriptive-name: nitrogen

molecular-weight: 28.02

critical-parameters:

critical-temperature: 126.2

critical-pressure: 3.39e+06

critical-molar-volume: 0.089

critical-compressibility: 0.288

acentric-factor: 0.037

- name: NO

descriptive-name: nitric-oxide

molecular-weight: 30.01

critical-parameters:

critical-temperature: 180.15

critical-pressure: 6.52e+06

critical-molar-volume: 0.058

critical-compressibility: 0.252

acentric-factor: 0.585

- name: O2

descriptive-name: oxygen

molecular-weight: 31.999

critical-parameters:

critical-temperature: 154.58

critical-pressure: 5.02e+06

critical-molar-volume: 0.074

critical-compressibility: 0.287

acentric-factor: 0.020

General Guidance

The Homogeneous-Reactor parses the input YAML file assuming that the order of the species at the top of the mechanism file is the same order that the species entries lower in the file will appear.